Upgrade Your Logistics Game: Why the 1100×1100 Reversible Pallet P1111WSE is Your Next Warehouse MVP

If you’re managing a modern warehouse, distribution center, or complex supply chain, you know that efficiency isn’t just a goal—it’s the foundation of profitability. Every piece of equipment, no matter how simple, must pull its weight. And when it comes to the heavy lifting—literally—the humble pallet is often the unsung hero that determines your operational speed and safety.

But are your current pallets holding you back?

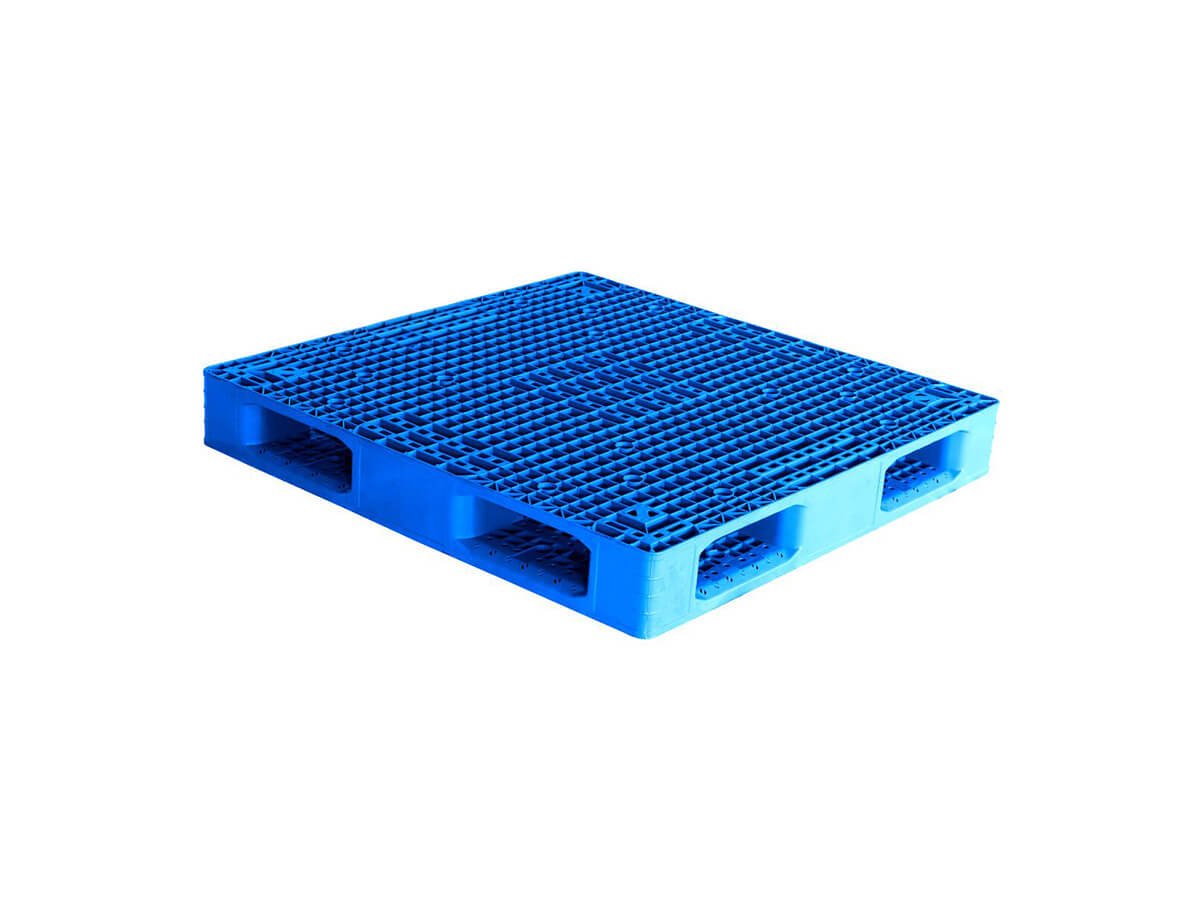

We’re here to introduce you to a game-changer built for enduring performance and maximum flexibility: the 1100×1100 Reversible Open Deck Rackable & Stackable Plastic Pallet P1111WSE. This isn’t just another platform; it’s a meticulously engineered solution designed to solve the common pain points of material handling, offering unparalleled durability, hygiene, and versatility across virtually every industry.

Ready to see how this single investment can optimize your entire logistical flow? We’re going to walk you through exactly why the P1111WSE deserves a permanent place in your fleet.

1. The Core Foundation: Engineered for Excellence

The P1111WSE is specifically sized at 1100 mm x 1100 mm, a square footprint highly favored in many European, Asian, and specialized industrial applications because it maximizes space utilization both in shipping containers and standard racking configurations.

However, the size is just the starting point. What truly sets this model apart is the robust synergy of its highly sought-after features: reversible functionality, an open-deck design, and the ability to handle demanding racking loads.

The Power of Reversibility: Doubling Your Value

The term “reversible” in the P1111WSE indicates a true double-sided design. This means that the top and bottom decks are identical and interchangeable, allowing you to use either side for loading.

What does this mean for your operation?

- Extended Lifespan: If one side takes minor damage or excessive wear, you simply flip it over. You are effectively doubling the usable life of the pallet compared to traditional nesting or non-reversible designs.

- Simplified Handling: There is no “right way up.” This eliminates human error during automated or high-speed loading processes, ensuring faster throughput and reduced delays on the factory floor.

- Versatile Load Distribution: The double-sided design often provides superior, balanced load stability, particularly useful when handling heavy or flexible products.

The Open Deck Advantage: Hygiene and Speed

Unlike closed-deck pallets which have a solid, impenetrable surface, the P1111WSE features an open-deck structure. This design choice is critical for industries where sanitation and quick processing are paramount.

The open structure:

- Facilitates Cleaning: Water, chemicals, and steam can pass straight through, ensuring complete cleaning and rapid drying. If your operation demands high levels of hygiene—think food processing or pharmaceuticals—you need this feature.

- Reduces Weight Traps: There are fewer places for dirt, debris, or moisture to accumulate, minimizing the risk of contamination or mildew growth.

2. Stability Meets Strength: Rackable and Stackable Mastery

When you invest in a premium plastic pallet, you are primarily buying long-term stability and specific load capacity guarantees. The P1111WSE delivers exceptionally on both fronts.

Rackable Performance: Safety in High Places

A pallet is “rackable” when it can safely hold a loaded weight (dynamic load) and be placed into an unsupported beam or slotted racking system without the risk of deflection or catastrophic failure.

For you, the warehouse manager, the rackable designation of the P1111WSE is a promise of safety and efficiency in vertical storage. This pallet is engineered with internal structural integrity and often reinforced (often with steel rods, hence the ‘WSE’ or similar reinforcement naming convention) to prevent bowing even when supporting thousands of pounds high up in a bay. If your facility utilizes high-bay racking, this feature is non-negotiable.

Stackable Efficiency: Maximizing Floor Space

When empty, plastic pallets must nest or stack cleanly to save space. The P1111WSE’s stackable design ensures that you can store a significant number of pallets in a small footprint. This immediate optimization of valuable floor space directly translates into cost savings. Furthermore, when loaded with goods, the flat, sturdy base allows for secure multi-level stacking, optimizing storage density in your staging areas or during transit.

3. Technical Specifications: The Numbers You Need

Before integrating any new material handling asset, you need to know the hard numbers. The table below outlines the core technical specifications of the P1111WSE pallet, ensuring it meets the demands of your toughest operations.

| Specification | Detail | Benefit to You |

|---|---|---|

| Dimensions (L x W) | 1100 mm x 1100 mm | Ideal for container and standard racking optimization. |

| Material | Virgin HDPE or Recycled PP (High Density Polyethylene / Polypropylene) | High impact resistance, consistent performance in varied temperatures. |

| Design | Reversible, Open Deck | Dual usability, superior sanitation, quick drying. |

| Tare Weight (Approx.) | 20 – 25 kg (Varies based on reinforcement) | Heavy-duty construction ensures maximum rigidity under load. |

| Dynamic Load Capacity | Up to 2,000 kg | Ability to safely handle heavy loads moving via forklift. |

| Static Load Capacity | Up to 6,000 kg | Securely stackable when motionless in the warehouse. |

| Racking Load Capacity | Up to 1,200 kg | Guaranteed safety and stability in high-bay racking systems. |

| Entry Type | 4-way Entry | Maximum handling flexibility for forklifts and pallet jacks. |

4. The ROI and Sustainability Factor

Plastic pallets, particularly those built for long-term use like the P1111WSE, provide a significant Return on Investment (ROI) over traditional single-use options.

Durability vs. Wood Pallets

Think about how often you deal with splinters, sharp nails, inconsistent weights, and the costly maintenance of wood pallets. The P1111WSE eliminates these hassles entirely.

| Feature Comparison | P1111WSE Plastic Pallet | Traditional Wood Pallet |

|---|---|---|

| Lifespan | Up to 10+ years | 6-12 months |

| Maintenance/Repair | Minimal; highly chemical and weather-resistant | Frequent repairs; splintering, warping, nail replacement |

| Load Consistency & Tare Weight | Highly consistent; known load deviation | Inconsistent; prone to weight variation due to moisture |

| Hygiene & Washability | Excellent; fully washable (HACCP compliant) | Poor; absorbs moisture and harbors bacteria/pests |

| Certification (Export) | Exempt from ISPM-15 | Requires costly heat treatment (ISPM-15) |

A Commitment to Sustainability

If your company has mandated sustainability targets, choosing reusable plastic pallets is a clear step forward. A single P1111WSE can replace dozens of wood pallets over its lifespan, drastically reducing the waste stream. Furthermore, these pallets are often manufactured from recycled materials or, if made from virgin plastics, are fully recyclable at the end of their long life, completing the circular economy loop.

By choosing the P1111WSE, you are investing in a product that not only cleans up your warehouse floor but also cleans up your environmental footprint.

5. Ideal Industries for the P1111WSE

The P1111WSE’s blend of hygiene, durability, and high load capacity makes it suitable for almost any sector, but it offers critical advantages in specific environments:

- Food and Beverage (F&B): The open deck and superior washability meet stringent HACCP and FDA guidelines, eliminating microbial contamination threats common with wood.

- Pharmaceutical and Biotech: Consistent weight, non-absorbent material, and cleanability ensure product integrity and validated material handling processes.

- Automotive and Manufacturing: The high racking load capacity supports heavy, valuable components safely in automated storage and retrieval systems (AS/RS).

- Retail and E-commerce Logistics: Durability and dimensional consistency are key for rapid, high-volume automated conveyor systems.

Conclusion: Securing Your Future Operations

The 1100×1100 Reversible Open Deck Rackable & Stackable Plastic Pallet P1111WSE is designed to be the backbone of your modern, efficient logistics program. It demands less maintenance, offers superior protection for your goods, and stands up to the rigors of automation and high-bay storage better than almost any alternative.

Stop settling for pallets that splinter, rot, or buckle under pressure. It’s time to equip your team with the P1111WSE—the robust, reliable, and hygienic solution that future-proofs your supply chain.

Frequently Asked Questions (FAQ)

Q1: Can the P1111WSE be used in Freezing or Refrigerated environments?

A: Absolutely. The P1111WSE is typically manufactured using HDPE (High-Density Polyethylene) or high-grade Polypropylene (PP), materials known for maintaining their structural integrity and impact resistance across a broad temperature spectrum. You can use this pallet effectively in temperatures ranging from well below freezing (e.g., -20°C) up to high heats without significant risk of warping or brittleness.

Q2: How does the load capacity change if the pallet is reinforced?

A: Reinforcement—often achieved using steel rods embedded inside the plastic structure—significantly increases the racking load capacity. While the dynamic (moving) and static (stacked) loads remain high, the key advantage of reinforcement is its ability to prevent deflection when the pallet is placed across open beams in a racking system. If you plan on using this pallet in automated, high-bay warehouses, always specify the reinforced version (like the ‘WSE’ variant) to ensure you achieve the advertised 1,200 kg+ racking load.

Q3: Is this pallet suitable for automated conveyor systems?

A: Yes, the P1111WSE is highly suitable for automated systems. Plastic pallets offer superior dimensional consistency compared to wood—they don’t warp, swell, or splinter. This reliable dimensional stability is crucial for smooth traction and trouble-free conveyance through automated lines, greatly reducing the risk of jams and downtime.

Q4: How do I clean and sanitize the open-deck pallet?

A: The open-deck design makes cleaning exceptionally easy. You can use standard industrial washing equipment, high-pressure washers, steam cleaners, or chemical sanitation solutions. Because the deck is open, water runs straight through, preventing pooling and ensuring all surfaces are exposed and can be quickly disinfected and dried.

Q5: If the pallet is reversible, how does a pallet jack or forklift access the bottom structure?

A: While the decks are reversible and structurally identical top and bottom, the design maintains 4-way entry. This means there are dedicated openings on all four sides of the pallet, allowing the forks of a forklift or pallet jack to easily enter and exit the structure, regardless of which side is used for the load.

Reviews

There are no reviews yet.